Page 30 - ingenioren

P. 30

Fuel Filtration

Overview

FUEL FILTRATION Fuel System Profile Fuel Filtration Design Considerations

At the end of this publication is a

“tear-out” profile form for you to

To properly apply fuel filter systems

travels through the transfer pump it

use to convey your system needs to

Donaldson engineers. there must be careful consideration of becomes mixed in with the fuel in

smaller droplets (called emulsified

many different factors. Mainly, there

needs to be an understanding of what water). Typical micron (µ) ratings for

The system profile has a list of all is being protected and what level of suction side primary filters vary over a

the design considerations required protection is required. Also, there wide range. Depending on the vehicle,

for proper engineering review to needs to be a general understanding engine and operating environment,

determine which Donaldson fuel of the fuel system, where the filters primary filters rated as low as 7µ

system would be the optimum are going to be placed and what to over 25µ may be employed. The

solution. the operating parameters are. Most efficiency of the primary filter, at a

fuel filters used in the engine fuel minimum, is determined by the pump

• Fuel System Characteristics - fuel filter market are located in one of requirements, but is usually selected

grade, reservoir capacity, fuel flow two positions, primary (pre-filter) or to help balance filter system life.

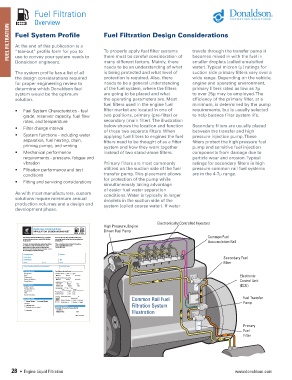

rates, and temperature secondary (main filter). The illustration

below shows the location and function Secondary filters are usually placed

• Filter change interval of these two separate filters. When between the transfer and high

• System functions - including water applying fuel filters to engines the fuel pressure injection pump. These

separation, fuel heating, drain, filters need to be thought of as a filter filters protect the high pressure fuel

priming pumps, and venting system and how they work together pump and sensitive fuel injection

• Mechanical performance instead of two stand-alone filters. components from damage due to

requirements - pressure, fatigue and particle wear and erosion. Typical

vibration Primary filters are most commonly ratings for secondary filters in high

• Filtration performance and test utilized on the suction side of the fuel pressure common rail fuel systems

conditions transfer pump. This placement allows are in the 4-7µ range.

• Fitting and servicing considerations for protection of the pump while

simultaneously taking advantage

of easier fuel water separation

As with most manufacturers, custom conditions. Water is typically in larger

solutions require minimum annual droplets in the suction side of the

production volumes and a design and system (called coarse water). If water

development phase.

DRAFT - 05 Aug 2010

Electronically Controlled Injectors

High Pressure, Engine

ENGINE fuEl fIltratIoN systEm

applIcatIoN dEsIGN workshEEt Driven Fuel Pump

Common Fuel

This form is intended to be filled out by an engineer Upon receipt of the form, Donaldson will assess

or buyer that interested in a custom FUEL filtration your requirements and get back to you within three

design system. working days. Accumulation Rail

For proper development/design engineering solution, When completed, please forward to Donaldson.

we ask you to provide details about your engine, Email: engine@donaldson.com

project due dates, fuel system and performance Fax: 952-887-3059

(mechanical and filtration), system mounting, service,

final packaging and product markings.

Company Name: Revision:

Project Name: Secondary Fuel

Contact Name: Title

Phone: Fax: Email: Filter

Current Donaldson Model Used: (if applicable) Your Part Number:

Engine Information Fuel Delivery System Brand: __________________

Manufacturer _______________________________ Fuel Flow Rates: ¨ lpm or ¨ gpm

Model ______________________________________ Minimum ______ Normal ______ Maximum ______ Electronic

Displacement _______________________________ Fuel System Pressure (kPa):

Number of Cylinders _________________________ Minimum ______ Normal ______ Maximum ______ Control Unit

Annual Volume _____________________________

Temperature: ¨ º C or ¨ º F

Fuel: Min ______ Normal _______ Max _______

key project dates: Ambient: Min ______ Normal _______ Max ______ (ECU)

Design Proposal: ___________________________ Fuel Heating ¨ Yes ¨ No

Prototype Delivery: __________________________ Watts __________ Voltage __________

Design Freeze: ______________________________ Priming Pump ¨ Yes ¨ No

PPAP: _____________________________________ Air Relief Valve ¨ Yes ¨ No

Start of Production: __________________________

Water Separation __________% Fuel Transfer

fuel system profile Volume (ml)_________ Common Rail Fuel

Water Collection ¨ Bowl ¨ No-bowl

¨ Primary Filtration ¨ Secondary Filtration Water Sensor ¨ Analog ¨ Digital Pump

Fuel Type:

¨ Standard grade ________________________ mechanical performance Filtration System

¨ Biodiesel and max. content Hydrostatic Pressure Resistance (Burst):

__________________ Test Method : _______________________________

¨ Alternative:

_______________________________ Minimum Value: __________________kPA Illustration

More on next page.

Primary

Fuel

Filter

28 • Engine Liquid Filtration www.donaldson.com