Page 27 - ingenioren

P. 27

Fuel Filtration

Overview

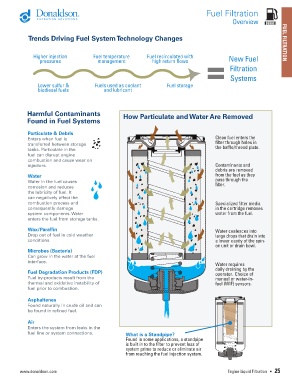

Trends Driving Fuel System Technology Changes FUEL FILTRATION

Higher injection Fuel temperature Fuel recirculated with New Fuel

pressures management high return flows

Filtration

Systems

Lower sulfur & Fuels used as coolant Fuel storage

biodiesel fuels and lubricant

Harmful Contaminants How Particulate and Water Are Removed

Found in Fuel Systems

Particulate & Debris

Enters when fuel is Clean fuel enters the

transferred between storage filter through holes in

tanks. Particulate in the the baffle/thread plate.

fuel can disrupt engine

combustion and cause wear on

injectors. Contaminants and

debris are removed

Water from the fuel as they

Water in the fuel causes pass through the

filter.

corrosion and reduces

the lubricity of fuel. It

can negatively affect the

combustion process and Specialized filter media

consequently damage in the cartridge removes

system components. Water water from the fuel.

enters the fuel from storage tanks.

Wax/Paraffin Water coalesces into

Drop out of fuel in cold weather large drops that drain into

conditions. a lower cavity of the spin-

on unit or drain bowl.

Microbes (Bacteria)

Can grow in the water at the fuel

interface.

Water requires

daily draining by the

Fuel Degradation Products (FDP) operator. Choice of

Fuel by-products result from the manual or water-in-

thermal and oxidative instability of fuel (WIF) sensors.

fuel prior to combustion.

Asphaltenes

Found naturally in crude oil and can

be found in refined fuel.

Air

Enters the system from leaks in the

fuel line or system connections. What is a Standpipe?

Found in some applications, a standpipe

is built in to the filter to prevent loss of

system prime to reduce or eliminate air

from reaching the fuel injection system.

www.donaldson.com Engine Liquid Filtration • 25