Page 128 - ingenioren

P. 128

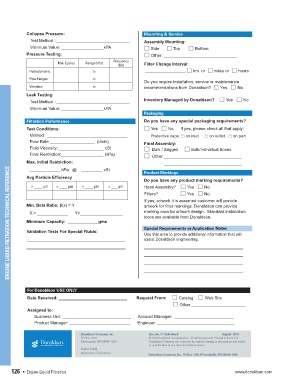

Collapse Pressure: mounting & service

Test Method : _______________________________ Assembly Mounting:

Minimum Value: __________________kPA ¨ Side ¨ Top ¨ Bottom

Pressure Testing: ¨ Other: _______________________________

Frequency

Min. Cycles Range (kPa) (Hz) Filter Change Interval:

Hydrodynamic to _________________ ¨ km or ¨ miles or ¨ hours

_

Flow Fatigue to

Do you require installation, service or maintenance

Vibration to recommendations from Donaldson? ¨ Yes ¨ No

Leak Testing:

Test Method : _______________________________ Inventory Managed by Donaldson? ¨ Yes ¨ No

Minimum Value: __________________kPA ___________________________

packaging

filtration performance Do you have any special packaging requirements?

Test Conditions: ¨ Yes ¨ No If yes, please check all that apply:

Method: __________________________________ Protective caps: ¨ on inlet ¨ on outlet ¨ on port

Flow Rate ___________________ (l/min) Final Assembly:

Fluid Viscosity: ___________________ cSt ¨ Bulk / Bagged ¨ Bulk/Individual Boxes

Final Restriction:__________________ (kPa) ¨ Other _________________________________

Max. Initial Restriction: _________________________________

ENGINE LIQUID FILTRATION TECHNICAL REFERENCE

_____________ kPa @ _________ cSt

product markings

Avg Particle Efficiency

Do you have any product marking requirements?

> ____ µm > ____ µm > ____ µm > ___ µm Head Assembly? ¨ Yes ¨ No

Filters? ¨ Yes ¨ No

If yes, artwork it is assumed customer will provide

Min. Beta Ratio: β(x) = Y artwork for filter markings. Donaldson can provide

X > _____________ Y>__________________ marking area for artwork design. Standard installation

icons are available from Donaldson.

Minimum Capacity: _____________gms

special requirements or application Notes

Validation Tests For Special Fluids:

Use this area to provide additional information that will

__________________________________________ assist Donaldson engineering.

__________________________________________ __________________________________________

__________________________________________

__________________________________________

__________________________________________

for donaldson usE oNly

Date Received: _____________________________ Request From: ¨ Catalog ¨ Web Site

¨ Other _______________________

Assigned to:

Business Unit: _____________________________ Account Manager: _________________________

Product Manager: __________________________ Engineer: _________________________________

donaldson company, Inc. doc. No. f115345 rev.0 august 2010

PO Box 1299 © 2010 Donaldson Company, Inc. All rights reserved. Printed in the U.S.A.

Minneapolis, MN 55440-1200 Donaldson Company, Inc. reserves the right to change or discontinue any model

or specification at any time and without notice.

Engine Liquid

Applications Engineering

donaldson company, Inc., po Box 1299, minneapolis, mN 55440-1299

126 • Engine Liquid Filtration www.donaldson.com